overview

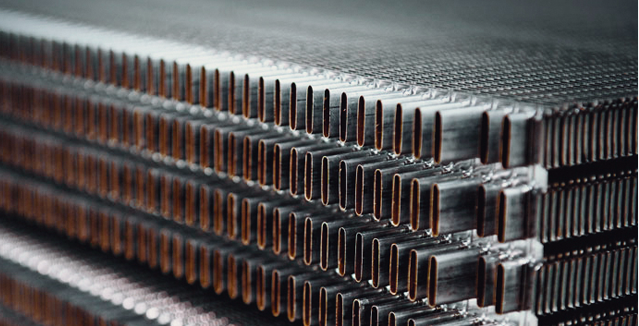

Industrial Radiator

Air Radiators provide high quality, reliable radiator systems for the Industrial market. Our products are durable and optimised for all applications, from severe duty equipment to smaller agricultural pumps.

Our customised radiator packages provide specialised cooling solutions for portable and stationary engines including:

- Dewatering pump sets

- Fire pumps

- Hydraulic systems

- Mulchers

- Farming harvesters

- Cranes

products

Air Radiators develops innovative Industrial solutions in partnership with you using a diverse range of products and configurations including:

case studies

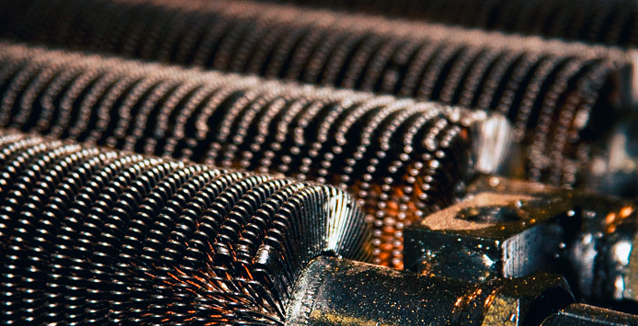

Application - Glycol/Water solution used in Freeze Drying process