overview

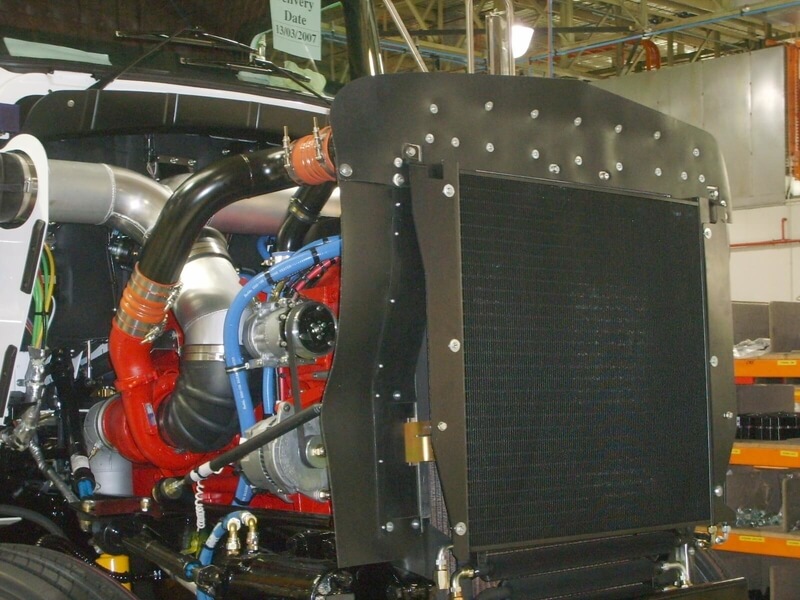

Air Radiators understand engine cooling applications and offer full design and manufacture of integrated cooling systems for mobile and stationary engines. We can combine multiple cooling duties for Jacket Water, Inter-Cooler Water Charge Air, Oil and Fuel to ensure maximum performance in the harshest conditions.

Air Radiators offer complete air-cooled radiator packages for:

- Small petrol engines to high horsepower diesel and gas engines

- Power generators

- Mobile equipment

- Compressors

- Pumps

SKID MOUNTED

- Engine jacket water

- Engine intercooler circuit

- Direct charge air-to-air cooling

- Fuel cooling

- Fan and fan belt cowling

- Fan and core guarding

- Plumbing kits

- De-aeration system – external and integral

- Fan impeller and fan pulley spacer

Horizontal Remote series

Horizontal remote series

- Water, Oil, Compressed air and process fluids

- Draw through fan design

- Modular construction

vertical remote series

- Water, Oil, Compressed air and process fluids

- ‘Blow through’ design duct mount fan

- Flexible installation (direct mounting, wall mounted or free standing)

V-PACK

- Footprint reduction

- Flexible design and robust construction using Coil, Pin Fin or traditional Core product