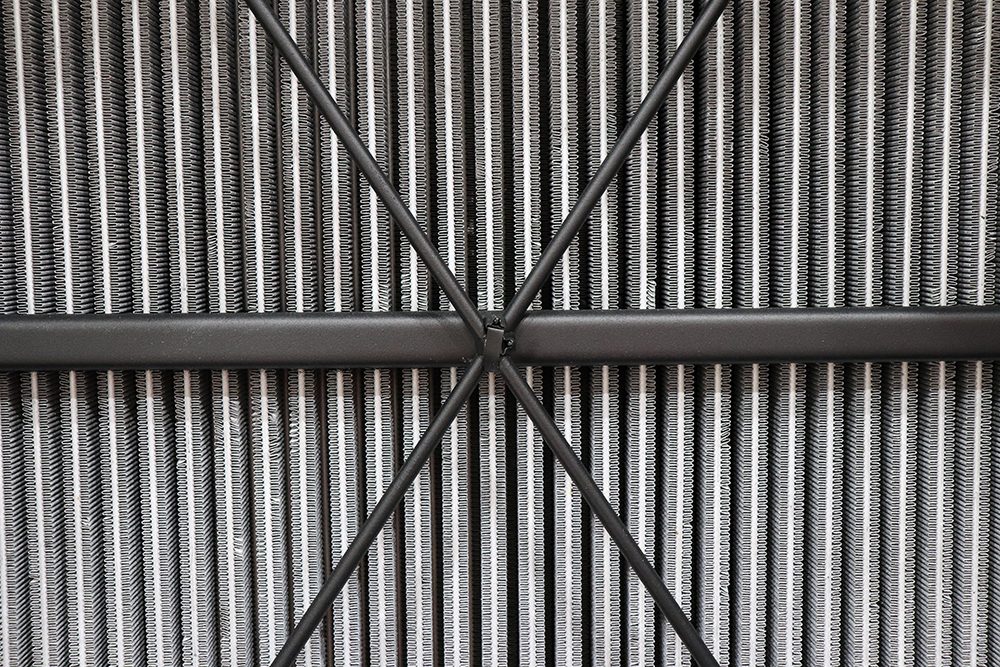

Alu fin

Alu Fin heat transfer products are comprised of individual finned aluminium tubes flexibly mounted. The high strength, light weight tubes…

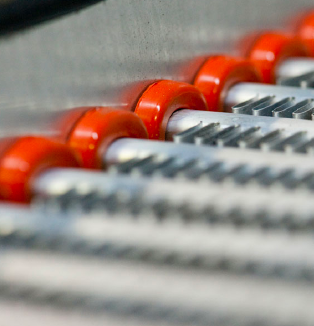

pin fin

Pin Fin oil coolers use a high thermal efficiency heat transfer tube. Using helically wound copper wire, the external fin is mechanically bonded…

pin fin

Pin Fin oil coolers use a high thermal efficiency heat transfer tube. Using helically wound copper wire, the external fin is mechanically bonded…

pin fin

Pin Fin oil coolers use a high thermal efficiency heat transfer tube. Using helically wound copper wire, the external fin is mechanically bonded…

Ultra Fused

Ultra Fused is the leading tube-to-header joint technology in copper/brass radiator core design.

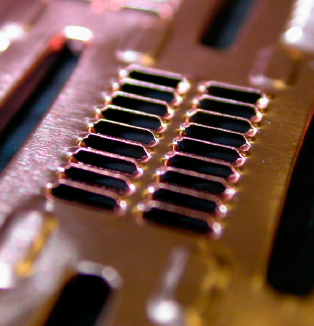

Ultra SEAL

This patented technology is a quantum leap forward in Charge Air Cooler design and provides the platform to meet…

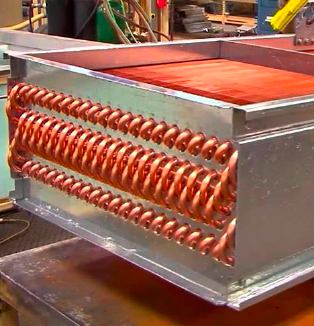

COIL

Combining the durability, corrosion resistance, and heat transfer capability of copper with the cost effectiveness of aluminium fin.

Mechanical Bond

Reduce running costs and improve engine efficiency with compact, self-contained designs with robust components for easy maintenance.

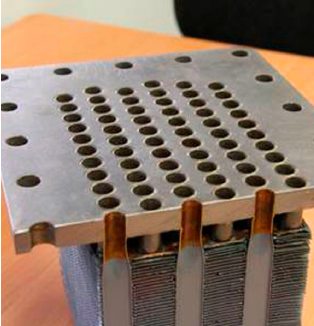

BAR AND PLATE

Bar and Plate is a high strength heat transfer surface, which offers a wide range of flexibility in design, construction and application.

FIN TYPE

Exposure to the elements is part of everyday life for a radiator system, so correct selection of our materials of manufacture is critical.