Industries

Power & energy generation

Air Radiators custom radiator packages serve engine cooling for portable and stationery gensets

Truck & Buses

Air Radiators’ custom radiator packages serve heavy transport, vocational trucks and buses performing in high duty cycles

Construction & Mining

Air Radiators delivers customised radiator packages serving surface mining, underground mining and materials handling.

DEFENCE

Air Radiators delivers specialised heat transfer solutions for the Defence market

Rail

Air Radiators provide radiator products to keep rail vehicles on track, providing cooling to engine, hydraulic and other systems.

Industrial

Air Radiators provide high quality, reliable radiator systems for the Industrial market from severe duty equipment to small agri pumps.

Oil & Gas

Air Radiators’ customised radiator packages are suited to the oil and gas industry.

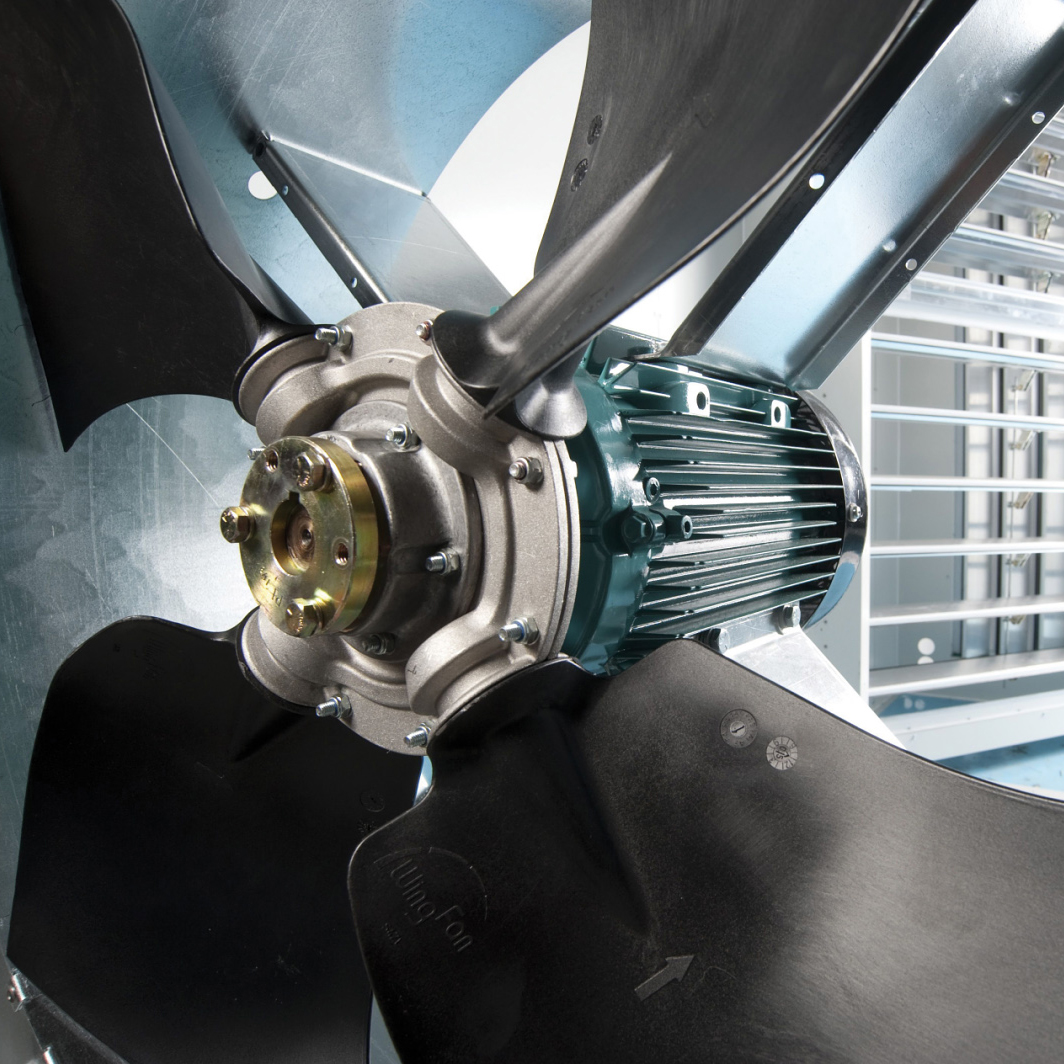

HVAC Solutions

Providing HVAC systems for use in extreme environments and ambient conditions in partnership with Booyco Engineering.