overview

Air Radiators oil coolers are manufacturing using various materials and are suitable across the hydraulic, fuels, process and transmission drive cooling markets. We can customise the design offering either packaged oil coolers (installed with radiator systems) or stand-alone units incorporating self-contained motors and fan drives to manage the heat.

Air Radiators broad range of Oil Coolers including:

- Aluminium Bar and Plate

- Brazed Steel

- Copper/Steel

REMOTE OIL COOLERS

- Broad range of cooler matrix, custom designed cabinets and high efficiency fans and motor assemblies

- Self-contained radiator groups

- Oil and viscous fluid cooling applications

- Available in singe and three phase motors

- Noise and wastes are minimised

- Incorporated modulating valves to manage start up bypass and pressure relief

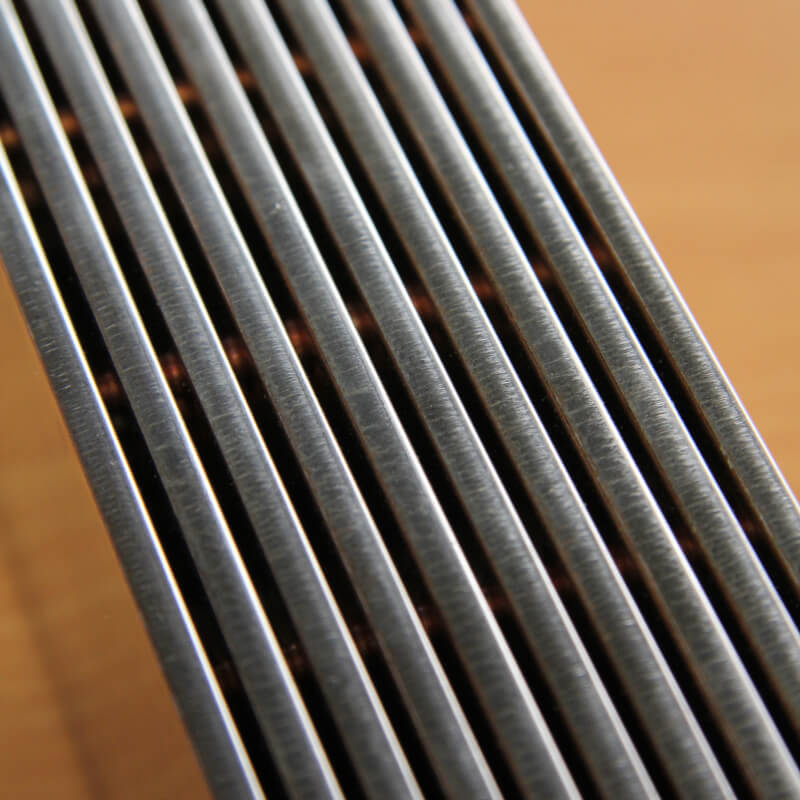

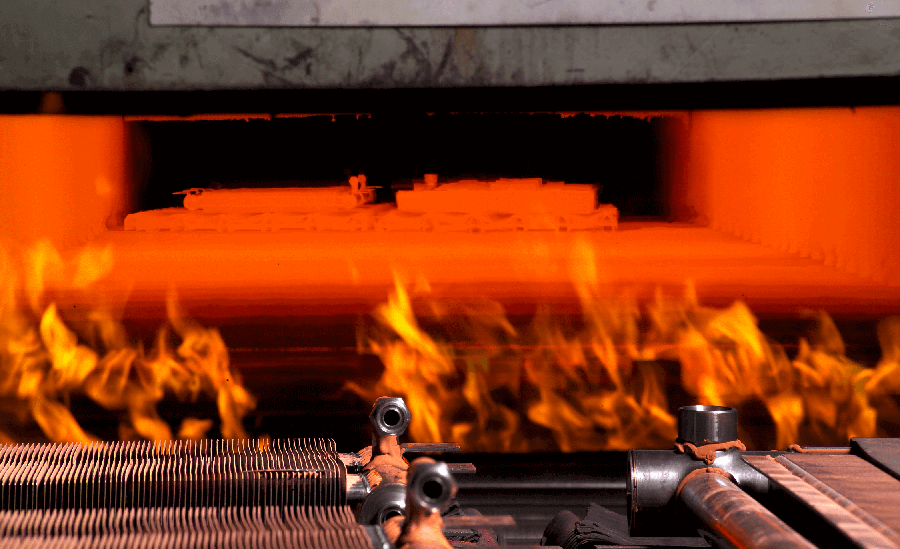

Steel Coolers

- Suited to harshest of operating environments

- Manufactured entirely from steel with copper braze

- 500PSI working pressure

- Durable steel fins can be power washed without deformation

- Fin spacing up to 8 FPI

- Optional integral by-pass (pressure or thermal)

- One, two, three or four row designs

Brazed Plate Coolers

- Compact, robust and efficient

- Cost effective and versatile

- Manufactured entirely from stainless steel

- Vacuum brazed to ensure no leaks

- Long service life and high strength

- Designed to be installed directly within a radiator coolant circuit, located within the radiator bottom tank or remote mounted within a separate manifold