overview

Air Radiators offer full design and manufacture of Air Coolers.

Air Radiators offer Air Coolers in:

- Copper/Brass

- Aluminium

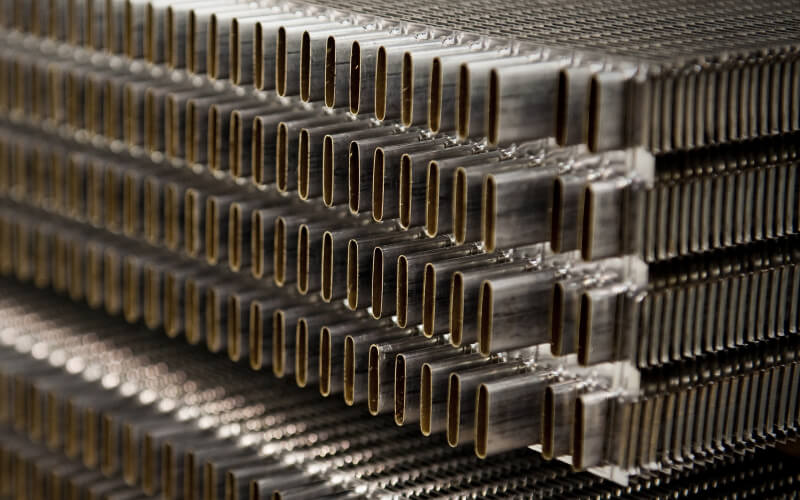

COPPER/BRASS

- Charged Air core is copper fin/brass tube heat transfer matrix specifically designed for Charged Air to Air Cooling

- Heavy duty features due to plate fin and tube core construction and Ultra Fused tube to header joint technology

- Flexible design, tailored to suit specific applications

- Solution for demanding Charged Air Cooler applications

ULTRA SEAL

- Patented technology

- Unique silicon grommet tube-to-header joint design

- High performance, durable and long service life

- Removes excessive stress caused by the thermal expansion, cyclic internal pressures and mechanical loads often associated with trucks, buses and specialty vehicles

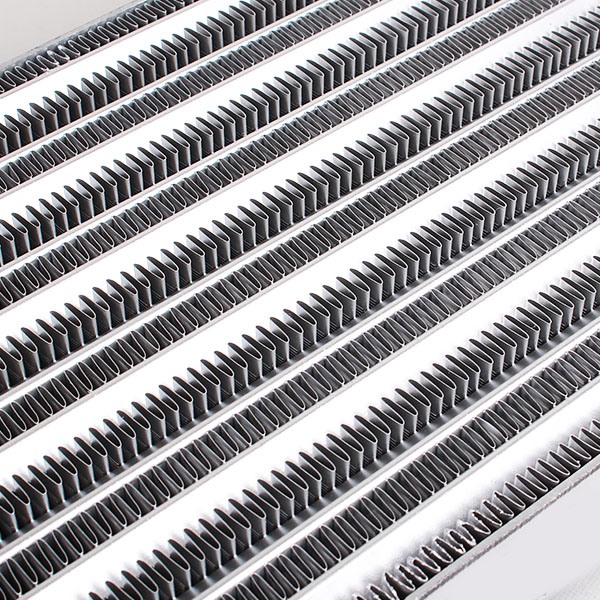

BAR & PLATE

- High strength surface offering flexible design, construction and application

- Entirely aluminium with excellent thermal efficiency suitable to high pressure applications

- Modular construction suits variety of internal fluids including aqueous (water based) solutions, gases (compressed air, engine turbo air) and oils

- Internal turbulators to enhance thermal performance

- Suited to pressures up to 500psi (3450 kPA)

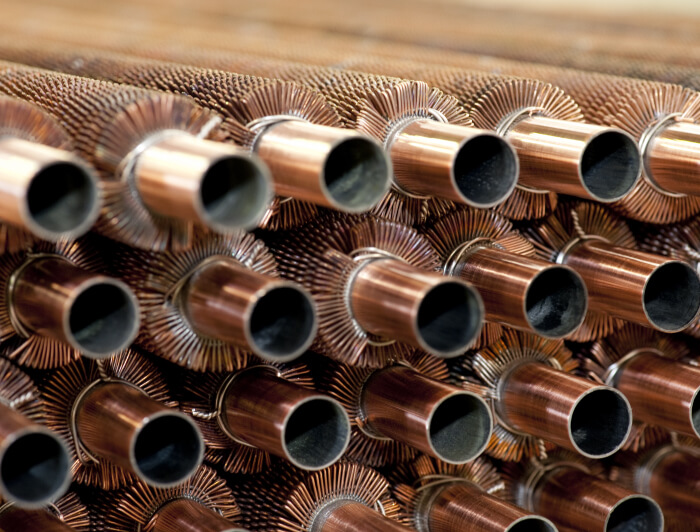

Pin Fin Coolers

- High thermal efficiency

- Helically wound copper wire mechanically bonded to the base tube via solder

- Suitable for variety of air blast cooling including process liquids and gasses, oil, diesel fuel, high pressure water and steam

- Manufactured using variety of base tube materials including copper, brass, copper/nickel, aluminium/brass, carbon steel, stainless steel and specialty metals like titanium

- Wire-wound internal turbulators to enhance thermal performance for viscous fluids

- Select from standard range of models or custom design